- An increasing number of jobs as well as digital printing advancements are forcing printers to redesign their workflow processes and use software to provide automation and optimization.

- Mass optimization can be defined as using metadata and software to automatically process all files for best function and fit, regardless of the output technology.

- When demand outstrips the working hours and capacity of the staff, automation can be a great way to help boost workflow efficiency.

By Ryan McAbee

Introduction

Over the past four years, the print service providers (PSPs) surveyed by Keypoint Intelligence have consistently identified dealing with a high number of small jobs as their top workflow challenge. As the number of jobs increases, it is difficult to scale labor to efficiently handle the increased workload—particularly if workflow processes have not been updated. Too often, the tasks and workflow processes are remnants from the days of analog printing, where fewer jobs and longer print runs were the norm. Today’s printers produce a high number of jobs—often at smaller quantities or in quantities of one—across a diverse set of digital and other printing technologies.

The Importance of Mass Optimization

Customers’ needs are evolving, and many might request office and marketing collateral as well as posters and signage in the same order from their preferred PSP. Each application will have a unique set of requirements, workflow tasks, and output technologies. The goal is to standardize the job onboarding and workflow processes for each application type so automation can be added to eliminate repetitive, routine tasks. Staff members can then focus on adding value to complex or bespoke work from customers.

Mass optimization can be defined as using metadata and software to automatically process all files for best function and fit, regardless of the output technology. Today’s PSPs must implement mass optimization techniques for time-consuming tasks like job onboarding, preflighting and file optimization, job batching, and creating smart impositions. There are a variety of well-established software solutions available on the market to address each of these challenges. These solutions can add incremental time and cost savings for every job that enters production, and even small changes can save big money!

The Job and Labor Pendulum

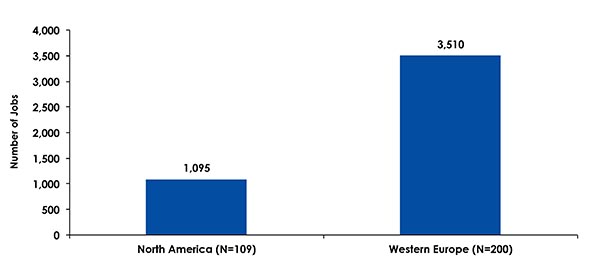

PSPs’ ongoing concerns about handling a larger number of jobs are well-founded. According to Keypoint Intelligence’s most recent European Software Investment Outlook, the average number of jobs produced increased by 77% between 2018 and 2019. During 2019, European PSPs averaged 3,510 jobs per month while North American printers averaged nearly 1,100 jobs. Assuming a 20-day-per-month schedule, printers are processing between 55 and 175 jobs per day.

Average Number of Monthly Orders

Base: Total Respondents

Source: NA and WE Production Software Investment Outlooks; Keypoint Intelligence 2020

This increased workload can only be offset with more labor hours or by implementing software-driven automation. Many PSPs have largely reached or exceeded their ability to apply additional staff at the increased order volume. Especially in these uncertain times, most PSPs are operating at the same staff capacity or less than in previous years and are therefore forced to do more with fewer people. Some of these service providers have shifted tasks that require less skill to lower-paid employees.

Keypoint Intelligence’s research reveals that whereas European printers have been more likely to shift preflighting and proofing tasks to customer support representatives (CSRs) to free up time for their more skilled prepress operators, North American printers have been more reluctant or fail to see the financial benefit. Simply shifting preflighting from a prepress operator to a CSR could save PSPs $5,621[1]per month or $67,452 per year—which is in the range of one full-time employee’s salary. At some point, demand outstrips the working hours and capacity of the staff. When this happens, automation can be a great way to help boost workflow efficiency.

The Bottom Line

The printing industry has undergone many pivotal, structural changes since Johannes Gutenberg’s invention of the printing press. We have experienced multiple waves of digitization, and it all started with desktop publishing in the 1980s. Now that we’ve entered another new decade, the next wave of changes will require printers to become efficient, data-driven operations that leverage mass optimization for their print production methods.

Ryan McAbee is a Director for Keypoint Intelligence's Production Workflow Consulting Service, which focuses on providing technology, business, and market insights to clients in the Digital Marketing & Media and Production Workflow markets. In this role, he is responsible for conducting market research, market analysis and forecasting, content development, industry training, and consulting with print service providers.

[1]Calculated from 14 minutes to preflight each job across 1,095 jobs per month using a CSR paid at $35/hour and a prepress operator at $57/hour.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free